Exergy — The Leading Source for Heat Exchangers Since 1979

For over four decades, we’ve exceeded expectations in service, quality, and value. Our compact, precision-engineered heat exchangers are tailored to your unique needs. Exergy engineers collaborate closely with you to deliver optimal solutions—on spec, on time, and on budget.

Product Lines

-

Sanitary Advanced heat transfer solutions that enable efficient thermal energy exchange and precise temperature control across critical applications.Learn More

Sanitary Advanced heat transfer solutions that enable efficient thermal energy exchange and precise temperature control across critical applications.Learn More- Shell & Tube

Design Benefits

- Compact Design

- Hydrophobic Coating

- Sanitary Compliance

- Double-Tube Sheet

Explore our Heat Exchanger SolutionsLearn MoreExergy designs its Sanitary Shell and Tube Heat Exchanger for processes requiring strict temperature control in a clean environment. Construction from 316L stainless steel or even exotic materials such as Hastelloy® and Inconel® provides for solid performance in both high-pressure, high-flow and corrosive applications.

- Heat transfer rates to 5,000,000 BTU/hr (1465 kW)

- Liquid flows to 250 GPM (946 LPM)

- Pressures up to 1,500 psi (104 bar)

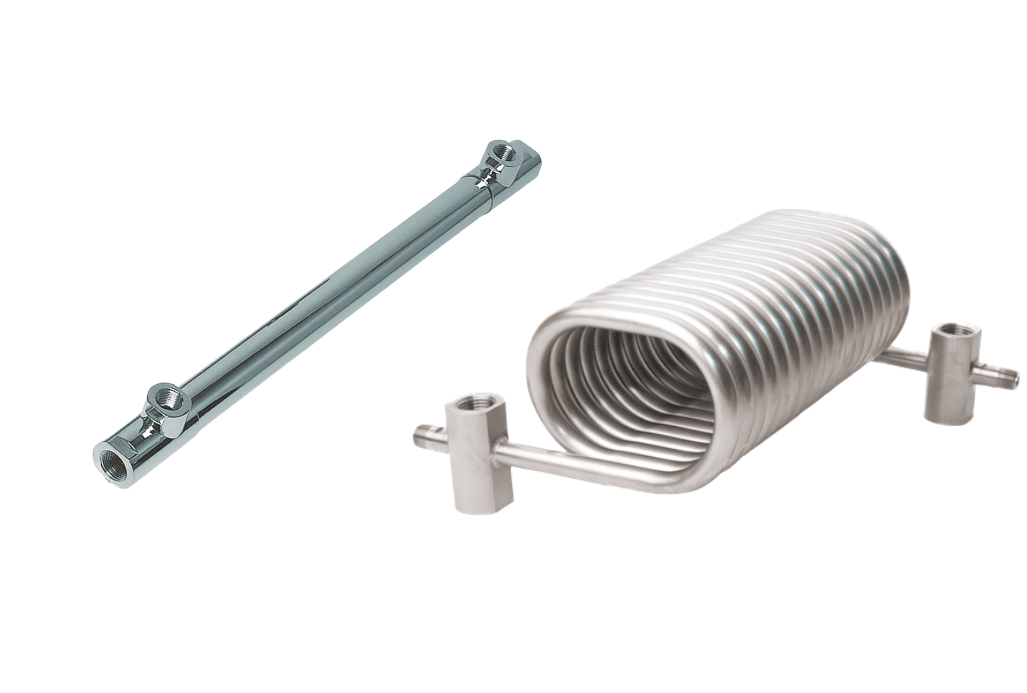

- Tube-in-Tube

Design Benefits

- Thermal Efficiency

- Sanitary Standards

- Maintenance-Free

Explore our Heat Exchanger SolutionsLearn MoreThe Sanitary Tube in Tube Heat Exchanger is ideal for low-flow, high-pressure applications where precision and hygiene are important. This model utilizes a dual-tube coiled design that allows maximum surface area when it comes to heat transfer, making it very efficient and, at the same time, resistant to thermal fatigue, even under most aggressive temperature conditions.

- Heat transfer rates up to 100,000 BTU/hr (29 kW)

- Liquid flows to 10 GPM (38 LPM)

- Pressures to 4,500 psi (310 bar)

- Shell & Tube

-

Process Heat exchangers deliver unmatched precision in temperature control for applications requiring exact thermal management.Learn More

Process Heat exchangers deliver unmatched precision in temperature control for applications requiring exact thermal management.Learn More- Shell & Tube

Design Benefits

- Compact Design

- Single Tube Sheet Design

- No Maintenance

- Material Versatility

Explore our Heat Exchanger SolutionsLearn MoreExergy’s low-flow process heat exchangers are engineered to deliver maximum thermal efficiency and reliability in demanding applications. Designed with a compact footprint and built for durability, these exchangers solve critical challenges like space constraints, precise temperature control, and harsh operating conditions.

- Heat transfer rates to 5,000,000 BTU/hr (1465 kW)

- Liquid flows to 250 GPM (946 LPM)

- Pressures up to 1,500 psi (104 bar)

- Tube-in-Tube

Design Benefits

- Thermal Fatigue Resistance

- Compact and Efficient

- Seamless Tubing

- Material Versatility

- No Maintenance Required

Explore our Heat Exchanger SolutionsLearn MoreExergy’s Tube in Tube heat exchangers are engineered for high-pressure, low-flow applications that demand durability and thermal efficiency. Their coiled design ensures maximum heat transfer while resisting thermal fatigue, even under aggressive temperature conditions.

- Heat transfer rates up to 100,000 BTU/hr (29 kW)

- Liquid flows to 10 GPM (38 LPM)

- Pressures to 4,500 psi (310 bar)

- Shell & Tube

-

PureX PUREX Systems are specifically designed to address these challenges, offering innovative solutions for managing Water for Injection (WFI) sampling.Learn More

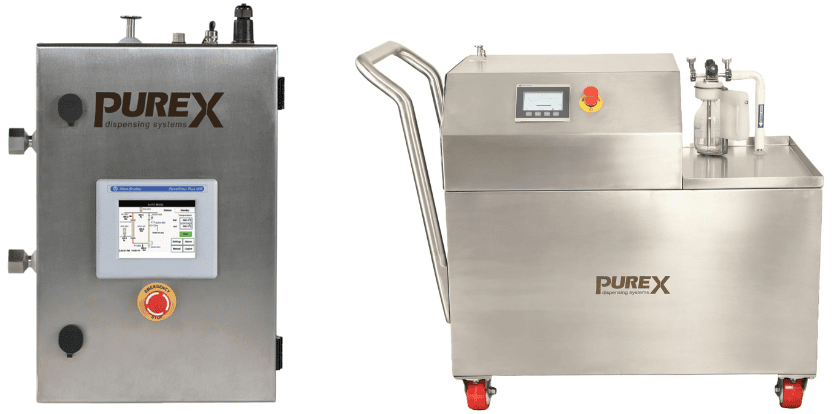

PureX PUREX Systems are specifically designed to address these challenges, offering innovative solutions for managing Water for Injection (WFI) sampling.Learn More- PureX Dispensing Systems

Design Benefits

- High Efficiency Design

- 5 GPM to 50 GPM

- Enhanced Safety

- Customized Expertise

Explore our Heat Exchanger SolutionsLearn MoreExergy’s PUREX Point-of-Use Dispensing Systems deliver greater manufacturing flexibility, less downtime, fewer contamination risks, and improved operator safety—all within a streamlined, automated solution. By supporting continuous production and boosting overall productivity, PUREX provides a rapid return on investment while enhancing compliance and reliability.

- Cool WFI/PW from 80-85°C to 20-40°C

- Water For Injection (WFI) systems

- Purified Water (PW) systems

- PureX Steam Sample Cooler

Design Benefits

- Mobility

- Ease of Use

- Versatile Cooling Options

- Durability and Reliability

Explore our Heat Exchanger SolutionsLearn MorePureX Clean Steam Sample Cooler is vital to pharmaceutical and biotech production, and verifying its purity is essential. The Steam Sample Cooler is purpose-built to deliver portable, precise steam sampling anywhere in your facility with confidence and ease.

- 1 Litre Sample volume 30-45 seconds

- Clean Steam Pressure 3.5 bar 50 psi

- Clean Steam Temperature 148°C 298°F

- Clean Steam Flow Rate 80 kg/hr 175 lbs/hr

- PureX Dispensing Systems

-

Custom Custom capabilities range from minor mods to completely new designs, providing the highest heat exchanger performance in the most compact package.Learn More

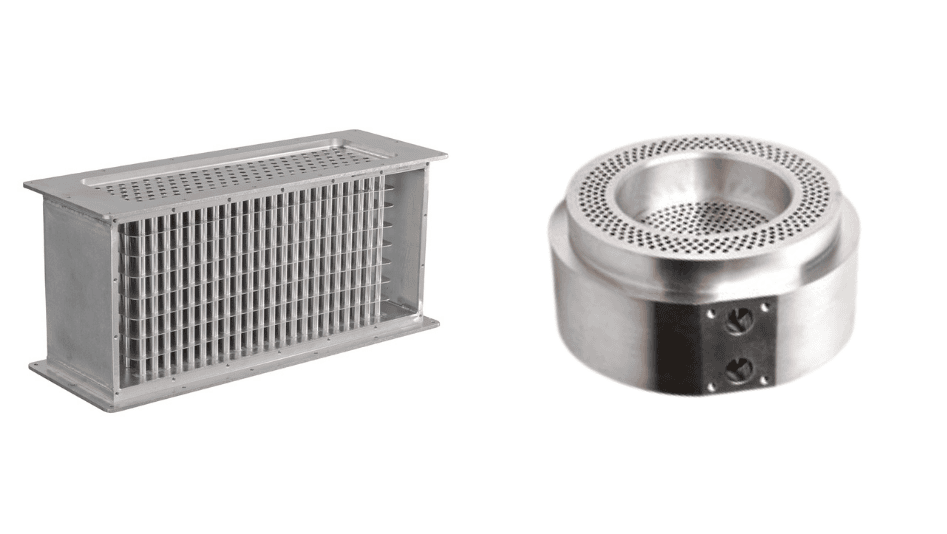

Custom Custom capabilities range from minor mods to completely new designs, providing the highest heat exchanger performance in the most compact package.Learn More- Custom Heat Exchangers

SPECIAL PROCESSING

- Passivation

- Electropolish

- Corrosion resistant coating

- Specialty cleaning processes

Explore our Heat Exchanger SolutionsLearn MoreExergy specializes in providing the highest heat exchanger performance in the most compact, cost effective package. If our standard products do not meet your requirements, we will apply our extensive experience and proprietary methods to create a custom design.

- Increased heat transfer or fluid flow rates

- Expanded pressure or temperature limits

- Assembly or integration of other components

- Integrated custom fittings or thread types

- Special tube size or count

- Special baffle configurations

- Special shell diameter and length

- Custom Heat Exchangers

Industries

Exergy heat exchangers are trusted across the most demanding industries—from sterile pharmaceutical manufacturing to high-performance semiconductor fabs. Wherever precision, durability, and efficiency matter, we deliver engineered solutions built for your process.

Explore Solutions by IndustryWhy Exergy

Sustainability

Sustainability

- Low thermal mass reduces utility consumption

- Durable materials extend equipment life

- Compact systems use less material and reduce facility impact

Safety

Safety

- Reduces risk to operators during WFI and clean steam sampling

- Prevents exposure to extreme temperatures or high-pressure utilities

- Supports SOPs and facility safety protocols with user-friendly design

Sterility

Sterility

- Zero-deadleg flow paths and sloped drainability

- Polished surfaces for aseptic integrity

- Full compatibility with CIP/SIP and validated cleaning procedures

Quality

At Exergy, our mission is to consistently deliver high-performance heat exchangers that meet or exceed customer expectations. We are committed to achieving error-free, cost-effective performance through continuous improvement, training, and employee engagement.

Testimonials

Trusted by Industry Leaders – Hear Their StoriesIn The Spotlight

Upcoming Events

Tradeshows 2025

ISPE Midwest May 23, 2025

Pharmintech Milan May 27-30,2025

ISPE DVC Philadelphia May 28, 2025

PCI Days Warsaw Germany June 11-13, 2025

Blogs

Why Choosing the Right Exergy Heat Exchanger Matters

When it comes to industrial processes, the right heat exchanger is more than just a piece of equipment – it’s a critical component that can impact the efficiency, safety, and cost-effectiveness of your operations. At Exergy, we understand that choosing the correct heat exchanger for your application can make a significant difference. In this post, we’ll explore why selecting the right Exergy heat exchanger matters, and how it can help your business save time, money, and energy.